Today, with a lot of hard pounding and some creative interpretation, the boys and their friends from Four Over The Edge got to make their own pewter bowls at the Royal Selangor Visitor Center. What an interesting adventure!

Royal Selangor was founded in 1885, when Kuala Lumpur was the epicenter of tin mining in the Malay Peninsula dating back to the mid 1800’s. The name Kuala Lumpur actually means Muddy River from all the tin mining of the time. As you probably know, tin is the main element in pewter so Kuala Lumpur was an ideal place from where Royal Selangor’s founder, Chinese pewtersmith Yong Koon, launched his company.

Today, Royal Selangor has become synonymous with high quality pewter and the company exports to countries worldwide. Their craft has even spread into silver and jewelry.

When first arriving at their showroom, the first thing I noticed was the enormous pewter beer tankard on display in front of the factory. With a capacity of 615 gallons of beer, it was recognized by the Guinness Book of World Records in 1987 as the largest beer stein.

We then proceeded into the factory where we were given a tour of the history of pewter in Malaysia as well as the company’s milestones.

Before the British introduced the tin dredge, tin was mined from the bottom of the rivers much as I picture gold was mined during the gold rush, by pulling up sediment from the river floor and shaking it in shallow wooden pans. We learned that in the early days, men were not even allowed to pan for tin as the theory was that they were not careful enough to have the job and too much would be lost.

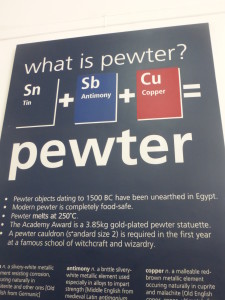

Pewter was originally made with mostly tin, mixed with antimony, copper and lead. These days, of course, lead is no longer used as it is toxic. Please note this sign explaining the ingredients in Pewter and a few important points. We got a kick out of number five.

We walked through Royal Selangor’s showroom, seeing the early tin “money” shaped as animal figurines. Since pewter is so soft, a leg would simply be broken off in payment. Also on display were early teapots, vases and ingots. From there, we learned about the weights and melting points of the various melts used in pewter making and what types of finishes are good for which products.

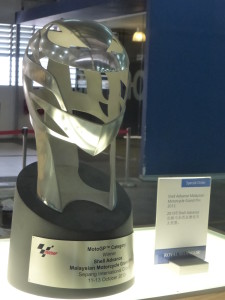

Finally, we were taken into the factory were we got to witness the production of all sorts of pewter items, including jewelry, teapots, and even trophies. (Did you know that the trophies for the Oscars are actually made from pewter with a 24K gold covering?) I couldn’t resist taking this trophy photo for my brother-in-law.)

Some of the pewter is melted and poured into molds. I was shocked at how it only takes a few seconds for the molten pewter poured into the molds to harden and be extracted. We watched a lady pour the 232 degree Celsius liquid into form for what I called Money Trees. These represent the coins as they were first used for trade.

We then watched another lady pound a perfectly even pattern around the outside of a cup. Then, we were given a go of it. Our pattern, shall I say, was much more “artistic.”

Last, but not least, was the School of Hard Knocks. The boys were given an apron and a flat piece of pewter to start. After engraving their names on the bottom, they were set loose with a mallet.

Last, but not least, was the School of Hard Knocks. The boys were given an apron and a flat piece of pewter to start. After engraving their names on the bottom, they were set loose with a mallet.

And, in less than 30 minutes, they actually pounded a pewter bowl with wooden hand tools much as it would have been done in the 19th century. They turned out great.

Both of the boys added some of their own artistic license to the bowl. Lorenzo added a rim, and Elio decided to give his bowl a flat bottom so it will sit without wobbling. At the end, they were each given an “original” certificate to accompany their bowls.

It was a fantastic morning and the boys all learned an awful lot. Plus, they are the proud owners of two of the greatest souvenirs from our trip!

WOW! What fantastic souvenirs! And how much you guys all learned there! And what fun too. These are things you can’t learn in a classroom, and so much more fun too.

I wish someone would take ME around the world with this kind of planning.

Im very happy to see and hear about this on your blog.

Omi

Yeah, it was a super fun experience. We all learned a lot! Thanks for commenting!

What a fun day that was. Your words and photos really captured it all. Safe travels.

Alana – Thanks, and thanks for being a huge part of the fun. I’m just mad I didn’t get a photo of all four boys holding their masterpieces! Keep in touch.

Fun! I didn’t even know this existed. Those bowls would go for $75 in a Northwest Portland boutique 🙂

Thanks Lindsay! So for 50 MR, it was worth doing, huh? Plus, we got all our aggressions out. 🙂